WIN the PitMaster HERE for Father’s Day, via our Facebook

page.

The knife, or more specifically the "edge” is the original tool used by man. Along with controlling fire, it was our yearning and desire as animals many years ago, to conceive and create these tools to manipulate our surrounding environment, which quickly defined our security at the top of the food chain.

Fast forward to the present day and the knife still remains a crucial tool in any Chef's armoury, with the fascination and necessitation of this tool hardwired into our DNA.

Acknowledging this connection of the biological imperative between man and blade, talented Melbourne based Bladesmith, Aidan Mackinnon has created niche company, Cut Throat Knives, crafting one of a kind, hand-built pieces.

Discovering knife making through a simple love of cooking,

Aidan saw knives as the primary interaction between ourselves and food, seeking

to enhance this joy by creating one off, long-lasting and well-built customised

products which will stand the test of time.

Cut Throat Knives has now grown to a team of three, with the addition of Woodwright and Bladesmith, Reza Balouri and apprentice Bladesmith, Faustina Delaney, together making a precise slice within the culinary industry which has seen them gain a fierce following and accolades, being awarded the Gold Winners of the 2017 Melbourne Design Awards and Delicious Magazine’s 2016 Artisan Produce Award.

As Father’s Day quickly approaches and we seek out those exclusive one-of-a-kind gifts, we thought there was no better time for our resident Chef, Shawn Sheather, who uses Cut Throat Knives himself as a chosen tool, to sit down and chat to Aidan, gaining an insight into his passion and creative process.

Aidan is now allowing one of our lucky readers the chance to win one of their most sought-after creations from the Cut Throat Knife collection, The PitMaster, hand crafted to complement our deepest primal instincts.

WIN the PitMaster HERE for Father’s Day, via our Facebook page.

We speak with Aidan Mackinnon from Cut Throat Knives

AGFG: The attention Cut Throat Knives has received must be great! To gain such interest and support from the industry is a true testament to what and why you do it, where do you gain your inspiration from?

Aidan: We are always blown away by the support and recognition that we have received. We've gone from a one person show to 3 people on staff and two contractors, we've been featured in a number of national and international magazines and won a number of awards and grants. It is incredibly humbling to have had the support that we've had to date. We've learnt a lot and we've got a lot more to learn.

We look to a lot of different places for our inspiration and we enjoy working with creative people. For me, I'm inspired by individuals or companies that are at the top of their game, who create excellence in what they do.

AGFG: We can see you have a genuine connection with your knives, after such personal work creating a knife, is it hard to let them go?

Aidan: Sometimes you just can't wait for a knife to leave your shop, other times you just never want to say goodbye, you've spent so much time holding this tool in your hand that it feels like a natural extension of your arm. The great thing is that the feedback we get years on from the initial purchase is that connection that the new owner has with their knife. We try to make more than just knives, we are trying to make kitchen heirlooms.

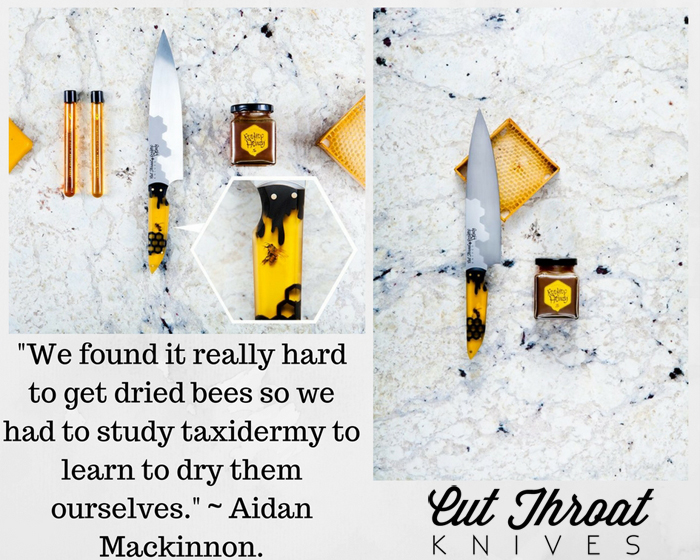

AGFG: You have partnered with several great companies, one of the latest is the "Rooftop Honey” company from Melbourne. How did the concept come about to encase a real bee within the translucent handle?

Aidan: Last year one of the first collaborations we did was with a florist (North St Botanical). We encased a flower in resin, at the time the resin artist that I worked with and I got chatting about how cool it would be to put an insect in there. We decided to reach out to Rooftop Honey with our idea. We pitched them the concept and they went for it, this all happened before we started making the knives. This knife has given me more headaches than any other, it seems simple but everything that could go wrong has. We found it really hard to get dried bees so we had to study taxidermy to learn to dry them ourselves, the resin and the bees kept on mixing weirdly and we had failure after failure after failure. The black honeycomb went through three iterations before we settled on the final product. All up it has taken 9 months to go from initial conversation to final product on this project, but the proof is in the pudding because we (both) couldn't be happier.

WIN the PitMaster HERE for Father’s Day, via our Facebook page.

AGFG: What inspired you to create the PitMaster? You mention it was "designed to make you feel like a warrior.” I’m sure there is more to this story.

Aidan: I love charcoal barbequing, so beyond the huge demand from interested customers for a brisket knife I knew I wanted to create a beautiful tool for the professional and hobbyist barbequer (including myself). Designing a new knife for us takes about 6 months, we sketch and play around with designs until we hit the right thing. With the PitMaster we combined a few different elements of knives and then matched the lines to a katana. A great knife does not only cut food, it evokes an emotion. Holding this knife really does give off a sense of power.

AGFG: The blade for such a "Warrior” knife must need some special steel work, run us through your process.

Aidan: The PitMaster that is available through AGFG is made with a stain resistant steel from Sweden called 12c27. It's a top performing steel that when heat treated takes a really good edge and holds it for a long time. Heat treatment is really the heart and soul of good knife making. You can have the best steel in the world but if you heat treat it badly it will not perform well. Without getting into too much jargon we heat treat our steels to the highest standard with temperatures accurate to within 2°C, our stain resistant steels are then all finished with cryo treatment where they are dropped to -80°C. The whole process takes a day and a half for each blade.

AGFG: You have created a limited number of PitMaster knives, all with an individually designed handle, give us an insight into what you selected for the AGFG giveaway knife, what should our winner expect?

Aidan: No two Cut Throat Knives are the same, we use a huge selection of exhibition grade wood that we source from a number of different suppliers from across the world. The PitMaster for AGFG was made with Bimble Box a native Australian wood. It is one of my favourite Australian woods and I have to hold myself back from putting it on all our knives. The handle boasts two small brass pins and one larger mosaic pin, that adds not only a huge amount of strength to the design but a touch of class.

AGFG: If you have a knife like the PitMaster, and you’re thinking about barbequing, and have a load of friends around, what’s your favourite item to cook?

Aidan: I will often cook 12-hour slow cooked rib rack when having friends over. I like mine dripping with sauce, I use my own sauce recipe that is inspired by Chinese Pork buns. It's either that or a whole beef loin cooked low over the charcoal. I then cut this up to bite sized portions with some board dressing and let people take it as finger food. During Summer my barbeque doubles up as my cold smoker for smoked salmon and homemade bacon. I do all of this from an apartment balcony, I can't let limited space get in the way of good food.

AGFG: We have noticed that you are now opening up the studio to classes, if we were thinking about attending, what could we expect? What is the focus during these classes?

Aidan: Our classes are an introduction into knife making where students design their own kitchen knife, cut, grind it out, heat treat it, finish the blade and put on the handle. We pack a lot into two days. We try to give a whole bunch of tips to the learner so if they want to go on and make more knives then they have a really solid foundation to do so. At the end of the two days you get to walk home with your own handmade knife, and hopefully a deeper appreciation for what it takes to make one.

AGFG: The past 2 years have been a success story for Cut Throat Knives, so what’s the focus for the next 12 months?

Aidan: The next

12 months are super busy, we are looking to move into our own concept store/ workshop/

foodlab, as well as roll out more limited editions, a full leather line-up and

early next year, dedicate a month to nothing but Butcher’s Knives. If that

wasn't enough we have two secret projects in the works and a trip to Japan and

Germany that we are hoping to take. Who needs sleep right?

WIN the PitMaster HERE for Father’s Day, via our Facebook page.

In a market saturated with disposable items, it is easy to see why there has been so much attention surrounding Cut Throat Knives, bringing to the table one-of-a-kind artisan products, crafted to execute precision for lifetimes to come.

For more information on Aidan, or to see the entire Cut Throat Knives collection, including wooden chopping boards and genuine Australian kangaroo leather knife scrolls lined with Marino wool, check it all out here.

Cut Throat Knives has gifted our readers $50 off any purchase of $500 until the end of the year. All you need to do is use the voucher code AGFGVIP, upon checkout.